3 fundamental truths for building your church’s new kitchen

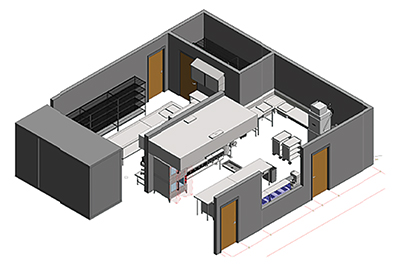

Along with all your other priorities in the new year, your church might be among the 54 percent planning to build, remodel or expand its kitchen* in 2020! If so, three fundamental truths can help you save time and energy, and protect your capital fund.

By Rhonda C. Proctor

TRUTH #1: Commercial kitchens are not residential kitchens

The projected life span of a typical church kitchen is 20+ years, so it must be designed and equipped for longevity and multi-functional durability. Pretty finishes are easily destroyed and porous surfaces are microbial nightmares, so you might as well learn to love commercial-grade open storage and the look of stainless steel. Yes there will be a few scratch and dents, but these surface blemishes rarely affect the operation.

Beyond the look, the complexity of your electro-mechanical equipment can be daunting. Although a kitchen’s planned use and design varies, there are some basics of foodservice equipment that always hold true:

- Buying new is your best insurance policy for energy efficiency and full warranty coverage.

- Mechanical connections must be carefully evaluated and incorporated into the design to avoid costly mistakes later

- Some foodservice equipment is built to order, and optional components are the norm.

- Local regulations can impact your choice.

- Value engineering is a necessity.

- Preventative maintenance is critical to equipment life so accessibility to mechanicals is critical.

- Always trust equipment installation to the professionals.

“There might be congregants with varying levels of expertise in the building trade, but few have trusted expertise in the foodservice equipment industry.”

TRUTH #2: Church kitchens are a specialized type of commercial kitchen

A church kitchen is a multi-purpose foodservice operation staffed with volunteers whose primary skill is fellowship, not food prep and serving. Here are some things you need for these operations:

More workspace — If you’ve ever observed the flurry of activity in a show kitchen, it’s like watching a choreographed performance with practiced performers. In a church kitchen, however, most volunteers don’t possess these skills, so your workspace must be designed to allow more people in the workspace. Extra worktables or hand sinks create natural, face-to-face fellowship opportunities.

Low-tech equipment controls — Foodservice equipment has gone high-tech. Even chefs who’ve spent a lifetime in the kitchen must relearn new cooking technology. In a church kitchen, however, equipment with simple-to-use controls will keep your volunteer base happy, and their fellowship strong.

High-tech holding equipment — The available technologies for holding food at safe temps for long periods of time is astounding. This is great news for all kinds of gatherings, from potlucks to major events, and it keeps the health department happy!

Focus funds wisely — Resist the urge to buy expensive slicers and food processors. Instead, redirect your funds toward prep, storage and serving needs. Follow the “51-percent rule,” if a piece of equipment will be used more than 51 percent of the time in your operation, consider purchasing it. If not, it’s likely a better idea to change how you buy food. Slightly more expensive prepared meats, as an example, might be a better choice than buying an slicer that sits idle most of the time.

TRUTH #3: Avoid buying large equipment online

In today’s Amazon-enabled world, this piece of advice might sound “old school.” But equipping a church kitchen is a complicated business, and specificity is essential.

Equipment options vary wildly, and the online item description rarely tells the whole story. We get inquiries all the time from people who have an equipment list from an online restaurant equipment retailer; they’re seeking guidance. This opens up a discussion of diagnosis and design; the equipment that has been selected (and appears on that list) often isn’t suited to the client’s operational needs or long-term goals.

It’s another issue entirely if incorrect items have already been purchased. Re-crating and packaging returns isn’t easy; restocking fees are costly; and freight claims are on the rise. And if you decide to sell what you don’t need in an online auction, know this: you’ll get about 10 cents on the dollar for your ‘used’ equipment.

Don’t underestimate the complexity

The bottom line is this: a commercial church kitchen is a highly specialized, complex endeavor. There might be congregants with varying levels of expertise in the building trade, but few who have trusted expertise in the foodservice equipment industry.

A good foodservice equipment dealer will have a history of teaming up with architects, general contractors and subcontractors to work with your team early in the design process. This simple decision will help you avoid costly mistakes later in the process that your congregation has to live with for years to come.

* Source: 2019 Church Executive Reader Survey

Rhonda C. Proctor is president of KECdesign, a kitchen equipment contractor and design firm headquartered in Champaign, Illinois. KEC’s 30-person team works with foodservice operations across the country to design, equip and install commercial kitchens on time and within budget.